Product Description

The Seeflex gauge meets the requirements of SOLAS (Safety Of Lives At Sea). It is also type approved by many worldwide shipping authorities including Det Norske Veritas (DNV), RINA, Lloyds Register of Shipping, Nippon Kaiji Kyokai, and Bureau Veritas. This gauge is commonly used for fuel oil, hydraulic oil, and lubrication oil tanks of cargo ships and work boats.

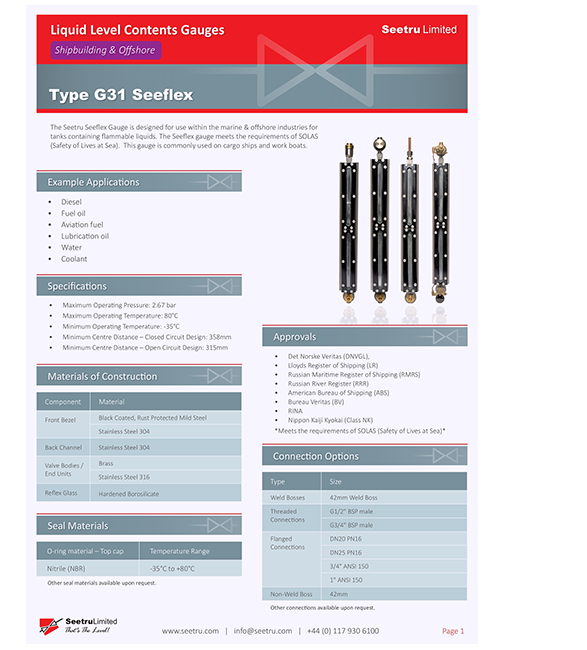

The G31 Seeflex Gauge

Technical Information for the Seetru G31 Seeflex Gauge

-

Maximum Temperature80°C

-

Maximum Pressure2.67 bar

-

Valve MaterialsBrass / Stainless Steel

-

Connections42mm weld bosses, mild steel or stainless steel Flanged or threaded connections available upon request

-

Seal MaterialsElastomer O'rings

-

GlassToughened borosilicate reflex glass DIN 7080/7081

-

Column MaterialsMild Steel, rust protected Stainless Steel

-

LengthsMaximum 8900mm

-

Valve TypesPush button self closing valves

Push-button operation

Except when a reading is being taken, the gauge is permanently isolated from the contents of the tank. To take a reading the spring-loaded valve is opened by pressing a push-button. When released, the connection between the tank and gauge is automatically resealed.

Safe from external damage

Due to the design of the push-button isolation valve, no amount of damage to the gauge or external fittings on the tanks can break the liquid seals. In such an event the fluid cannot escape.

Closed circuit design

The closed circuit design penetrates the tank wall at both top and bottom connections. The options for the top connection are either a push-button self-closing valve or valveless tank return.

Open circuit design

This is only allowable when it is possible for the gauge column to extend above the top of the tank by at least 100 mm. The upper end of the gauge can be supplied with an automatic safety vent valves or, alternatively, a pipe union connection. The automatic safety vent will allow air to pass, but will seal against a liquid level. In the case of the pipe union connection design, a 10 mm o/d steel vent pipe is returned to the tanks or into the tank vent pipe.

Hydraulic actuation

Hydraulic actuation can be supplied as an optional extra. This is designed to enable both push-button valves to be operated at the same time. Recommend for tall gauges where it would otherwise be difficult to operate the upper and lower push-button valves simultaneously.

Graduation

Where a measure of the precise storage volume is required, an engraved scale plate can be provided marked with the capacity units.

Durable Construction

Liquid-level indicators are built to withstand harsh environments. Look for models with corrosion-resistant materials, leak-proof seals, and robust designs for long-lasting performance.

Downloads

View or Download the Type G31 Seeflex Gauge Datasheet

Full Technical Information

View or Download the Type G31 Seeflex Gauge Datasheet

Seetru offers a wide range of downloadable datasheets for our products, including safety relief valves, liquid-level gauges, and sight glasses. These datasheets provide detailed information on the technical specifications, features, and applications of Seetru products. They are an essential resource for engineers, designers, and other professionals who need to select the right Seetru products for their specific needs.

Find your PDF Download for the G31 Seeflex below…

Visit our downloads page for other Seetru product brochures and catalogues

Contact Seetru